3 Preventive Electrical Service Strategies for Critical Industrial Infrastructure

Electrical systems serve as the backbone of productivity and safety. Whether powering essential machinery or ensuring uninterrupted operations, even minor electrical issues can lead to costly downtime and safety hazards. Implementing preventive electrical service strategies is necessary for maintaining operational reliability, extending equipment lifespan, and reducing the risk of unexpected failures. Below are three key strategies that every industrial facility should consider to keep its electrical infrastructure performing at its best.

1. Routine Infrared Thermography Inspections

Infrared thermography is a powerful, non-invasive method used to identify hotspots and irregularities in electrical components before they escalate into serious problems. By detecting temperature anomalies in switchboards, circuit breakers, and transformers, technicians can schedule repairs proactively and avoid unplanned shutdowns. This approach is especially critical in industries where uninterrupted power is essential for operations. Regular thermal imaging inspections, performed by certified Level II thermographers, help reduce the risk of fires and electrical failures caused by overheating.

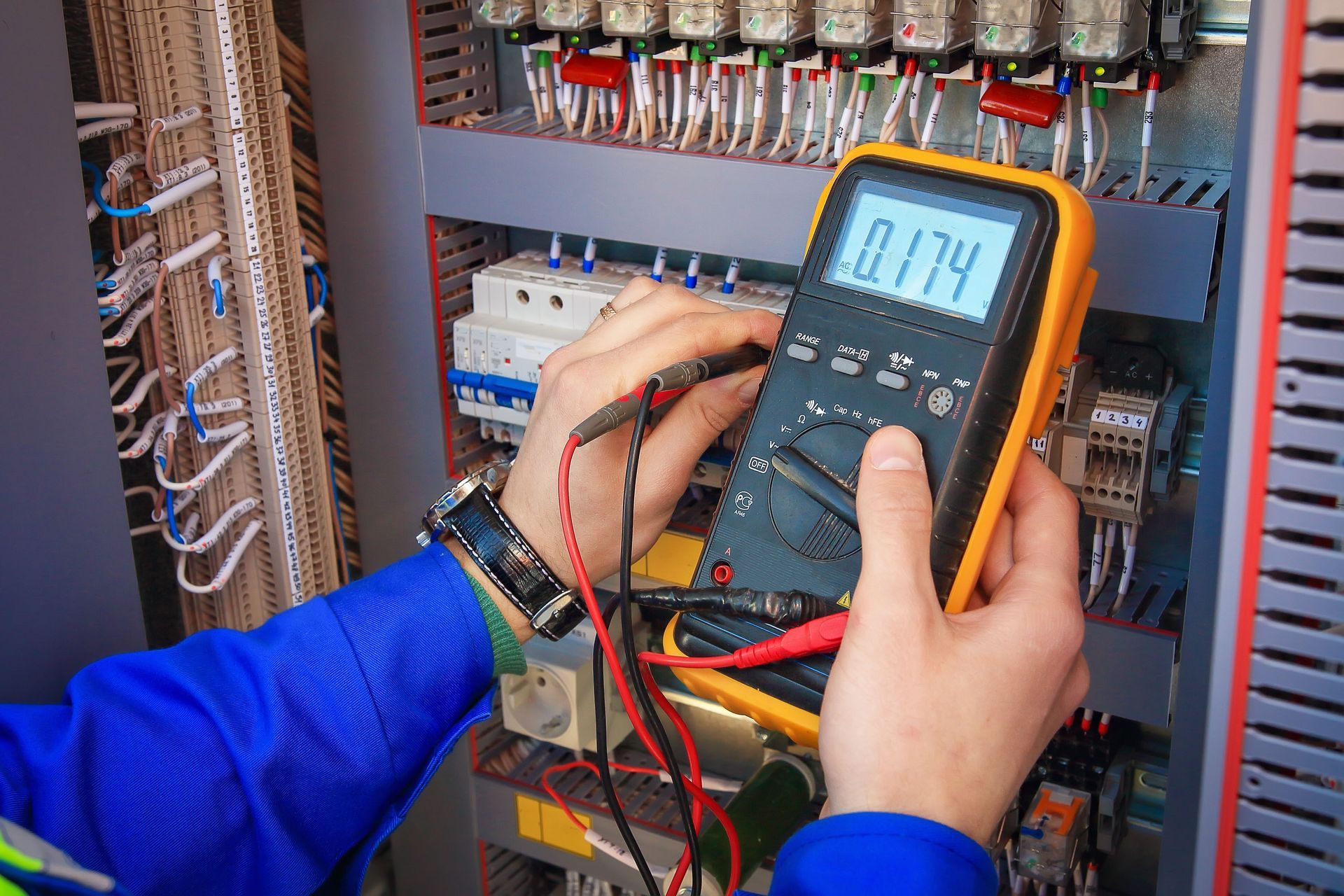

2. Circuit Breaker and Switchgear Maintenance

Both circuit breakers and switchgear components play a pivotal role in protecting critical industrial infrastructure from overloads and electrical faults. Preventive maintenance for these components includes cleaning, lubrication, mechanical inspections, and performance testing to ensure they operate within specified parameters. According to Zippia, there are over 303,823 commercial and industrial electricians across the U.S., many of whom specialize in maintaining these complex systems. Facilities that implement a scheduled servicing plan for their circuit protection equipment significantly reduce the chance of catastrophic failures and improve overall electrical system reliability.

3. Transformer Health Monitoring

Transformers are essential for regulating voltage and ensuring efficient energy distribution across industrial sites. Preventive strategies for transformers involve regular oil testing, bushing inspections, and load analysis to identify signs of wear or contamination. Catching minor issues early—such as insulation degradation or oil leaks—prevents costly replacements and extends the life of this critical equipment. Additionally, incorporating remote monitoring solutions allows for real-time tracking of transformer performance, further reducing the likelihood of unexpected disruptions.

Preventive electrical service strategies aren't just a best practice; they're an investment in the resilience and longevity of industrial infrastructure. From thermal imaging to circuit breaker maintenance and transformer servicing, each of these measures contributes to minimizing unplanned downtime and maximizing safety. In industries where even a brief power interruption can have substantial financial consequences, staying ahead with a proactive electrical maintenance plan is essential for long-term success.

Ensure your facility stays powered, safe, and efficient with expert

electrical service from Fielding Electric Inc. Contact us today to schedule preventive maintenance tailored to your property's needs.

Share On: